When designing and constructing external wall systems, the question often arises: Is a breather membrane always necessary?

Applying a breather membrane over sheathing boards installed on Steel Framing Systems (SFS) is strongly recommended for several reasons. This is evidenced by information from authoritative sources in the construction industry, some of which are set out below.

The Purpose and Function of a Breather Membrane

Breather Membranes provide an extra layer of weather resistance and are included within external-wall structures to increase the resistance to water ingress. Their inclusion or otherwise should not be dependent on the type of sheathing board being used.

Although most sheathing boards offer a measure of durability and water resistance, they are rigid panels with joints and fixings. Cement/calcium silicate boards resist water ingress, but moisture may eventually pass through if the board is subject to soaking. Gypsum boards have a glasmat top layer which, if penetrated, even with redundant screw holes or from mishandling or damage from other trades, can lose all structural integrity if it gets damp.

On the other hand, a Breather Membrane can be easily dressed, wrapped, and sealed (typically with tapes) around interfaces and penetrations, providing the structure with a much greater level of resistance to water ingress.

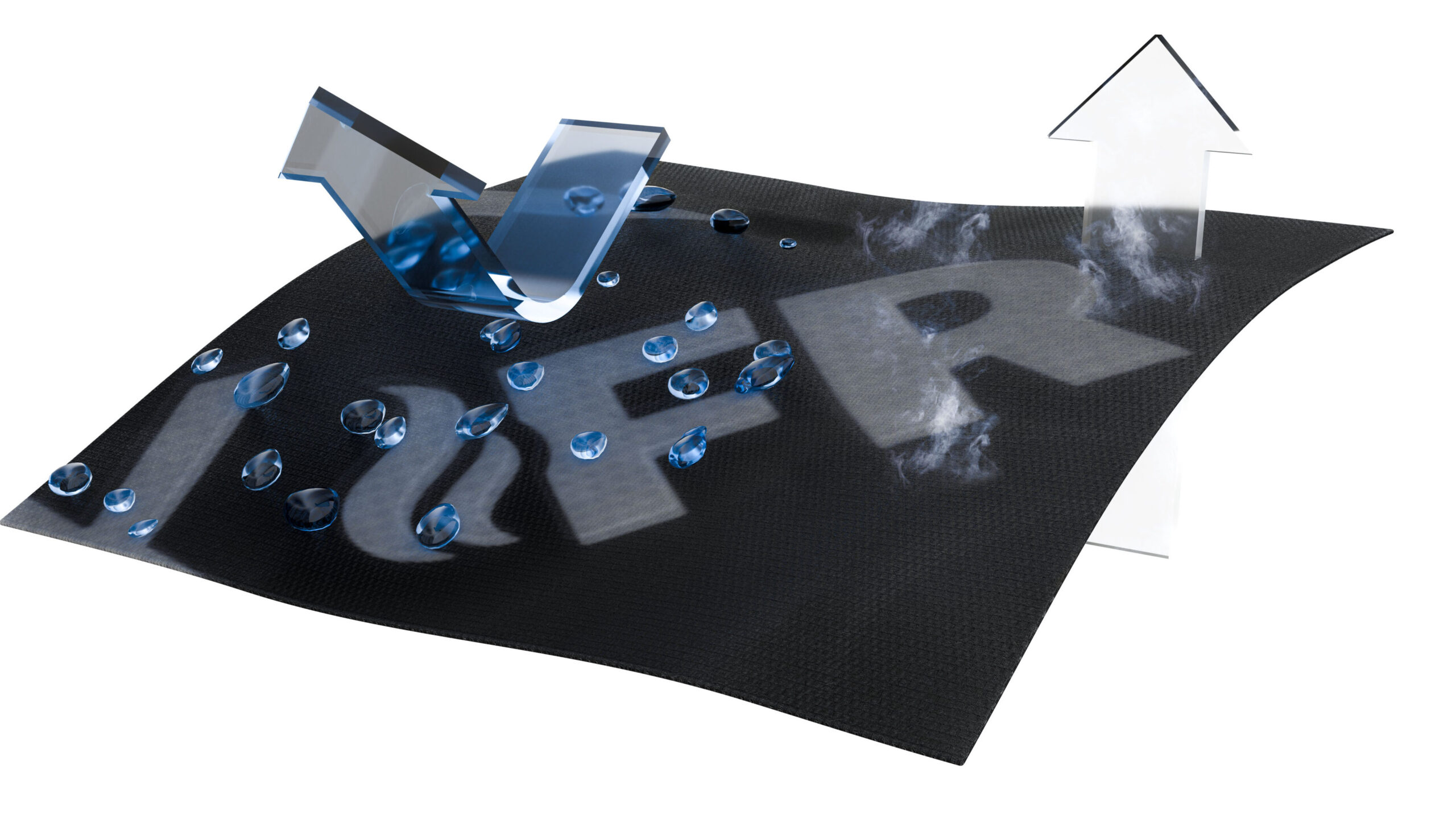

Even though the sheathing board may possess BBA certification, it does not eliminate the requirement for a Breather Membrane. A Breather Membrane uniquely acts as a barrier, preventing water from seeping inward through the wall whilst still allowing water vapour to diffuse outward, making it an essential element in façade through-wall systems.

Longevity and Durability

The concern is that without a breather membrane, excessive water and moisture will enter the external wall during construction and be unable to escape or evaporate once the façade is in place. This can lead to severe deterioration of the sheathing board, SFS and insulation. This moisture in the external wall can also cause dampness and mould internally, creating irreversible damage to the building.

Performance Standards

Breather Membranes, when tested, are required to achieve high levels of water resistance, such as a minimum W2 to BS EN 13859-2.

The Breather Membrane should satisfy several key criteria:

- It should carry suitable third-party accreditation for use as a breather membrane.

- Its vapour resistance should be less than 0.6MNs/g when tested in accordance with EN ISO 12572 set C and five specimens.

- The membrane should possess a minimum B-s1,d0 fire-classification according to EN 13501-1

- It should be rated at least Class W2 to BS EN 13859-2. In areas of extreme exposure or anticipated liquid water penetration of the facade, Class W1 should be used.

Environmental Benefits

Breather Membranes can contribute to a longer building lifespan, resulting in a lower embodied carbon footprint. The spread of embodied carbon over a more extended period reduces average annual emissions, making the buildings more sustainable and environmentally friendly in the long run. Breather membranes also contribute to airtightness, which improves the efficiency of the building.

Positioning and Functionality

The correct positioning of the breather membrane is crucial. It can be located either on the outer face of insulation within the cavity or on the outside face of the sheathing board.

Thermal Efficiency and Temporary Protection

Most W1 Breathable Membranes are also air-tight, improving the thermal efficiency of a building’s external envelope and providing temporary protection from the weather during construction or repair works. This dual function enhances both the building’s energy performance and its resilience during the construction phase.

Water Resistance and Vapour Permeability

Breather Membranes are water-repellent yet vapour-permeable, also known as microporous. As a rule of thumb, they are recommended to be 20 times more vapour permeable than the internal vapour control layer (VCL). These membranes prevent any moisture, snow, wind and contaminants that may penetrate through the cladding from further entering the structure, whilst their vapour permeability prevents the buildup of interstitial condensation.

Summary

In summary, installing Breather Membranes over sheathing boards is considered critical for superior performance in water resistance, durability, and environmental sustainability, as well as for achieving regulatory compliance with all applicable technical and performance standards. This ultimately ensures the long-term integrity and functionality of the building structure.

It is also to be noted that introducing a breather membrane does not remove the necessity for an Interface Sealing Membrane around the perimeter of the SFS panel at slab edge and column interfaces.

References:

Understanding why breathable membranes are required in external walls (pbctoday.co.uk)